Infrastructure

All our components are strong,adaptable and tested for quality .We provide Technical consulation,processing ,transportation, and development of product to our estmeed clientle to meet all scaffolding and formwork requirement mobilized by facilitiesbase .Each component is throughly tested and exmainde d at every stage right from sourcing to fabrication.Equipped with latest inspection technquies ,and strong technical team. Swati has quality control parameters so that we can deliver zero defect products.

- Sprawling Area of around 12500 Sq yard

- Drop Forging Hammers

- Scew Forging Presses

- Induction Billet Heaters

- Power presse Range from 5 Tons- 250 Tons

- In House Galvanizing plant

- In house facility for painting and powder Coating

- CNC Wirecut

- Electric Discharge Machine (EDM)

- CNC Pipe Cutters

- Vertical Machining Center

- CNC Turning Machines

- Multi Drilling Machines

- Shot Blasting Machines

- 5 station Nut Forming Machine & Nut Tapping Machine

- In House Spectrometer for Material Testing

- In House UTM For Scaffolding Couplers

- State of the Art CAD/CAM Infrastructure for 3D Modeling

- Riveting machines in Assembly Lines

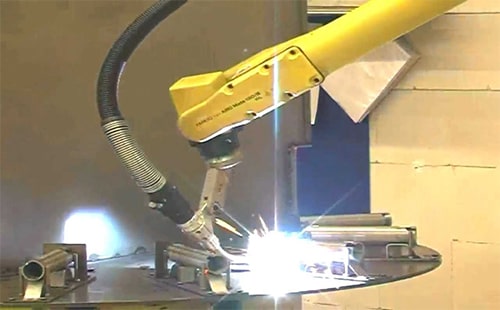

State Of Art Machinery

Our World Class equipment ensures best in class asspect added to each Swati Product .An additional yet important features which is follwed to meet the challenges invovled in residentail,commercial ,industrial and infrasructural services.

Our Successful track record in providing Scaffolding and works for refurbishment and new build projects bears testimony tothe Swati Commitment reinforced by the lastest machinery for the best results.